Insulation will not be able to keep pipes from freezing on its own in extremely frigid temperatures, however, insulation will prolong the time it takes for a liquid to freeze in a pipe, tank, or vessel. So while insulation can greatly increase the time it takes liquids to freeze in a pipe or vessel, as long as there is a temperature differential between the pipe or vessel and the ambient air, there will be heat transfer. Of course, it is important to note as well that how much longer it will take a liquid to freeze in such container varies drastically depending on a number of factors such as ambient temperature, pipe temperature, liquid temperature, and type of insulation.

To help ensure a pipe vessel or tank will not freeze, the heat (BTUs) being lost must be replaced by an outside source such as electric heating cable or circulation heat.

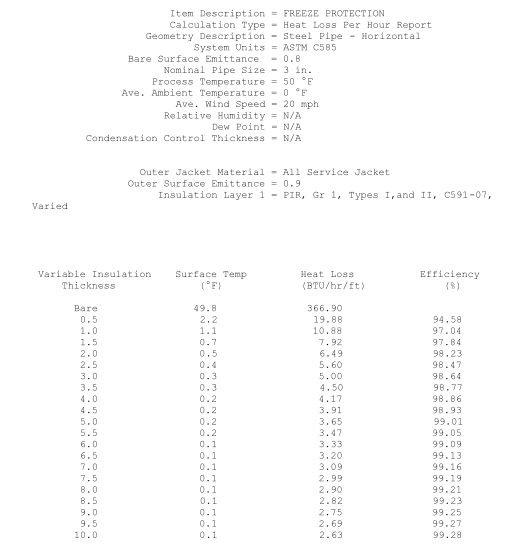

The greater the delta T, (or the difference between ambient air temperature and operating temperature of the pipe or vessel) the greater the heat loss. Couple this heat loss with a 20 MPH wind and the heat loss becomes exponentially increased.

Often times, insulation will reduce the rate of heat loss to such a great degree the pipe or vessel will not freeze. This can be quantified by a specialist certified to do heat loss analyses.

Below is a study of heat loss compared to variable insulation thickness. Evidently, as the insulation thickness, the heat loss decreases.

In addition to helping protect pipes from freezing, pipe insulation is good for energy conservation (as pipes require less energy to be heated when covered), noise control, and condensation control.

Visit our thermal pipe insulation page for more information.