Acoustic Wall Barriers

SOUND BARRIER ROLLS

48" x 50' roll (200 s.f.)

S.A.B. Sound Attenuation Board

This board has an NRC of 1.05 meaning by test measurements, it absorbs 5% more than 100%. The 100% was derived years ago and rated the best-known material of its time.

2' x 4' x 2" sheets

24" x 21" production cut-offs

Advantages

Barricade Noise Barrier is easily installed on walls, floors, and ceilings. Complicated construction is unnecessary. Low-cost solution for noise transmission problems

Construction

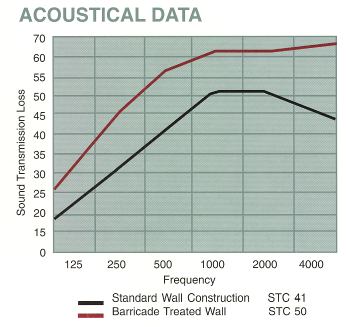

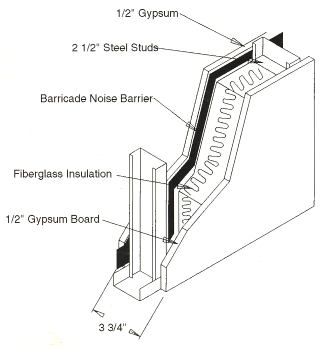

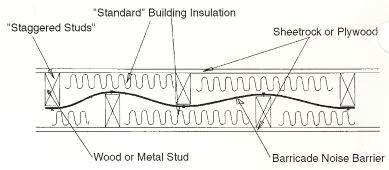

Barricade Noise Barrier may be installed in conventional wall construction or in a staggered stud assembly for higher STC results.

The barrier is like a big slab of 1/8" thick cheese, heavy and limp. The SAB is like a big shredded wheat. Both are easy to cut with a knife and neither are meant to be left exposed outdoors but could be left exposed indoors.

The actual difference between the "staggered stud" and the "standard stud" arrangement (diagrams below) differs very little with regard to acoustic performance. A great deal of difference can be realized by replacing the fiberglass filler with our S.A.B. (sound attenuation board) because it is roughly 10 to 12 times as dense as standard fiberglass batts while only 2" thick.

Official testing is not available using our S.A.B. as part of these 2 diagrams and therefore no published result can be provided. Tests do show that the NRC (Noise Reduction Coefficient) of Nominal 6 pound per cubic foot S.A.B. has an NRC of 1.05 (for 2" thickness) which is estimated to be 4 times higher than standard building insulation. Additionally, while it is not published, nominal 6 pound per cubic foot S.A.B. also adds to sound transmission loss (the actual reduction of sound transmission through a substance or combination of substances) because it weighs about 1 pound per s.f. (the same as the "EB1" barrier itself).

For better results still, consider using a decoupling layer of foam tape. (We stock this in 1-1/2" x 54' rolls. ) This is installed between the drywall and the barrier and/or the barrier and the framing members to "decouple" the sheeting from the rest of the wall system. See "helpful diagrams" below.

This system is the same or is similar to practices used in "Dyno Rooms" for testing motors for race cars and motorcycles.

The only way we know to beef this system up even further is to use 2 layers of the EB1 barrier or use cement blocks.

Weight/Sq. Ft. .......................................1 lb.

Tensile (Psi) .........................................762

Gauge (Inches) ................................... 108"

Elongation (%) .................................... 200%

Die "C" Tear (#/In.) ............................. 114

200ºF/7 days ....no deformation: <1% Shrink

Mil Std 6411 Burn Test ... Pass: Self Extinguished

STC ......................................................... 26